Our E2WA analyzer measures and detects energy losses in real time and reveals hidden saving opportunities across your industrial installations.

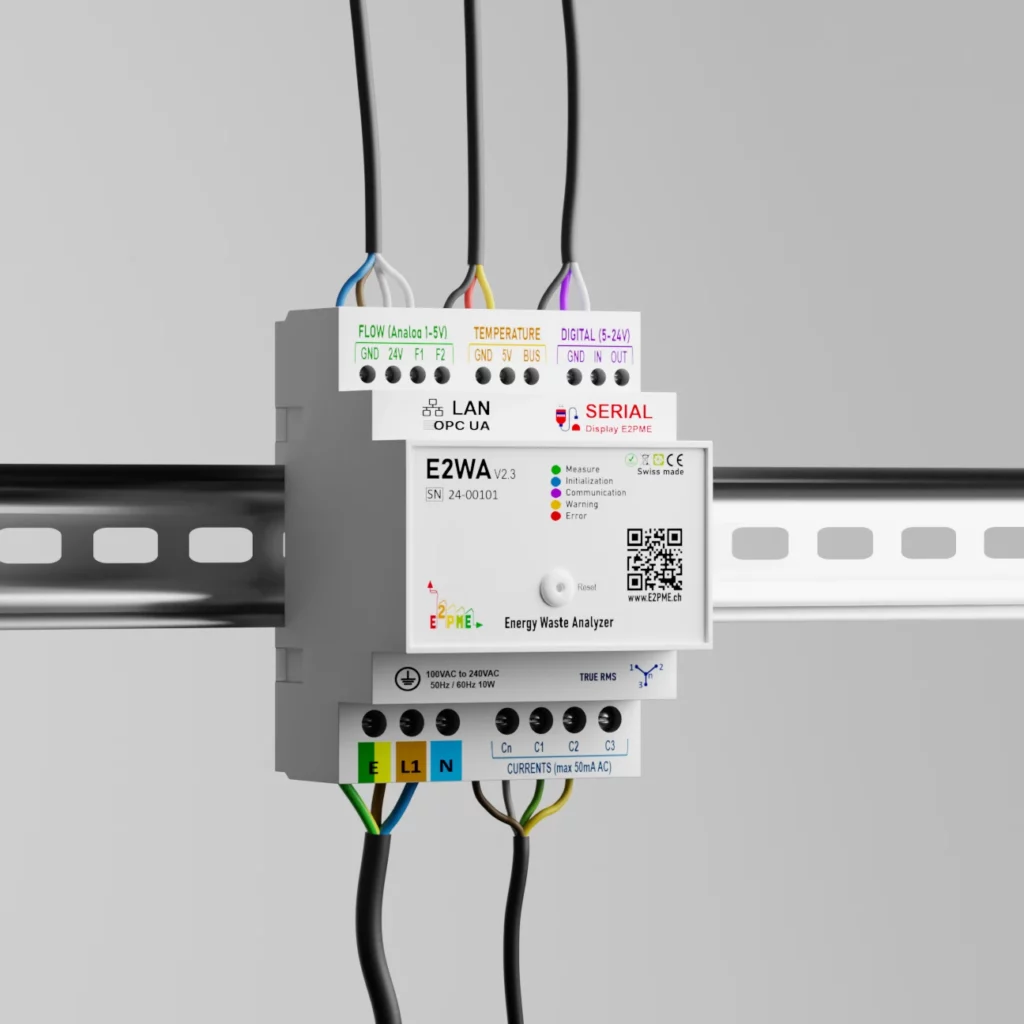

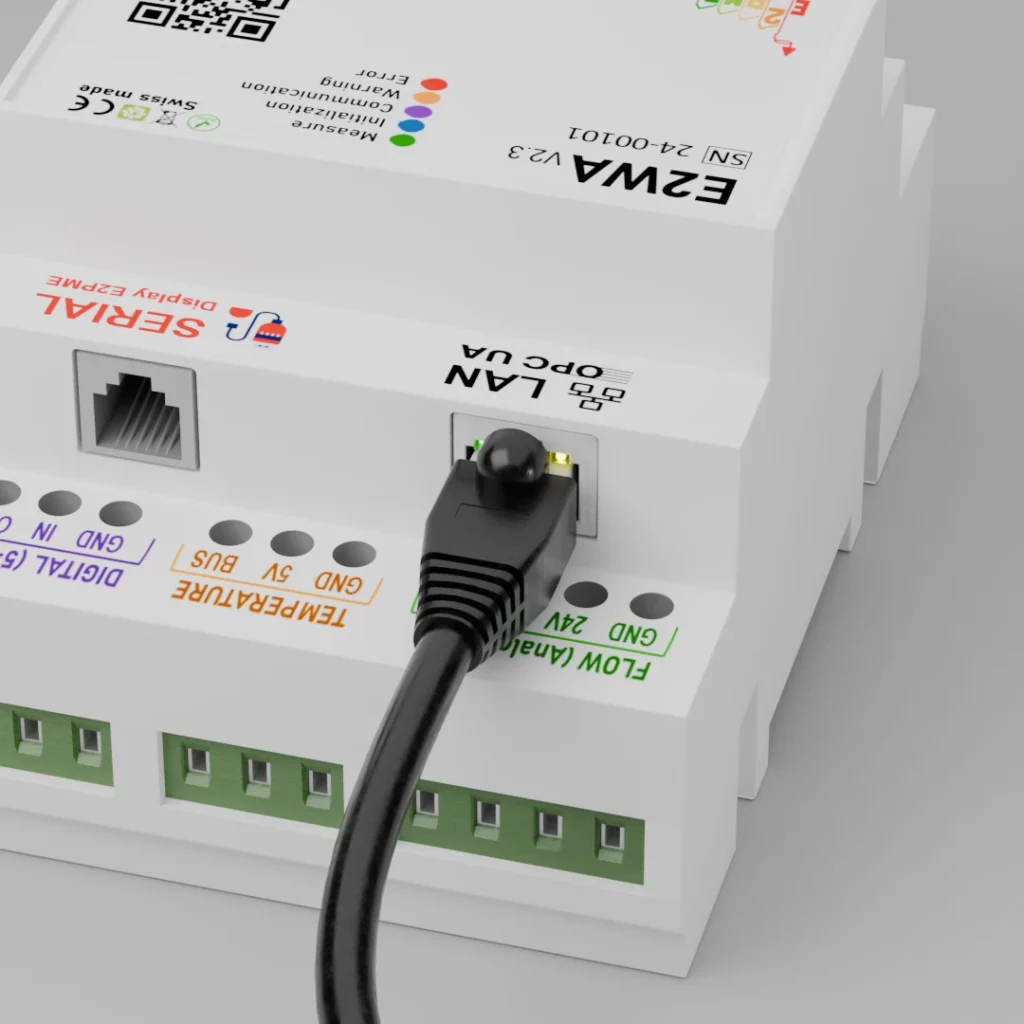

Our solution is built on a modular architecture, allowing you to connect only the sensors you need: electricity, compressed air, water, temperature, and more.

This flexible approach ensures a controlled investment and a perfect fit with your industrial environment.

With modular measurement, you get precise, relevant and targeted data without unnecessary complexity. Your infrastructure stays agile and scalable, ready to meet new performance and sustainability challenges.

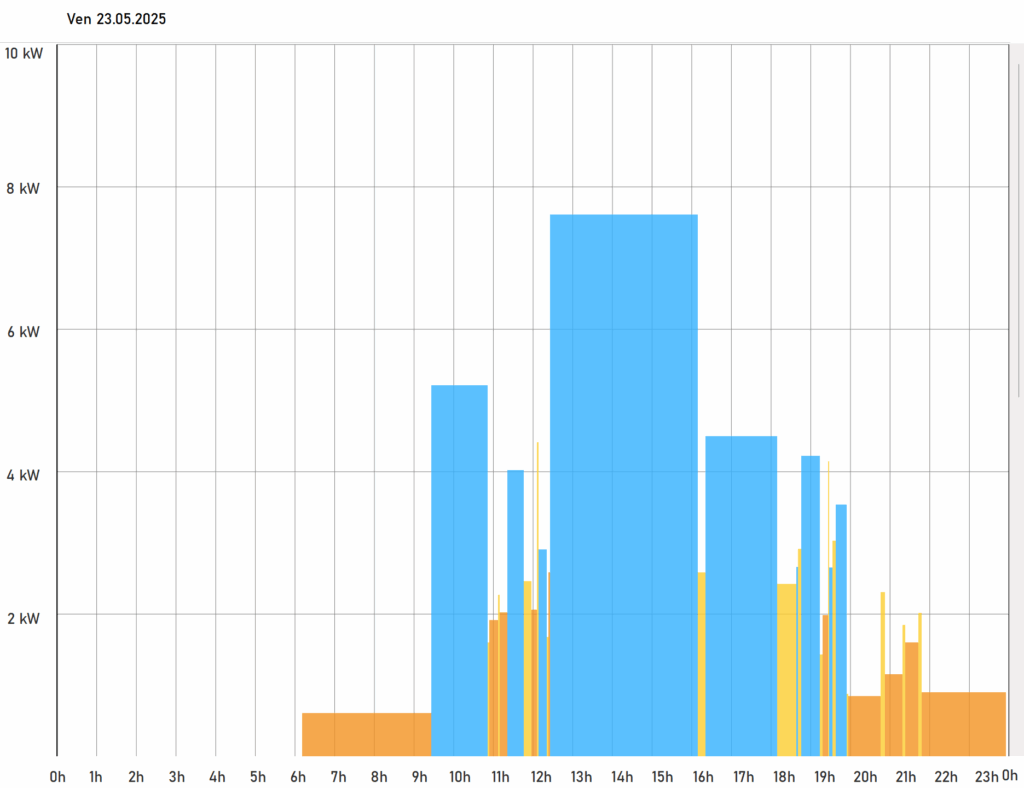

Measure power, current, voltage and deviations across your equipment.

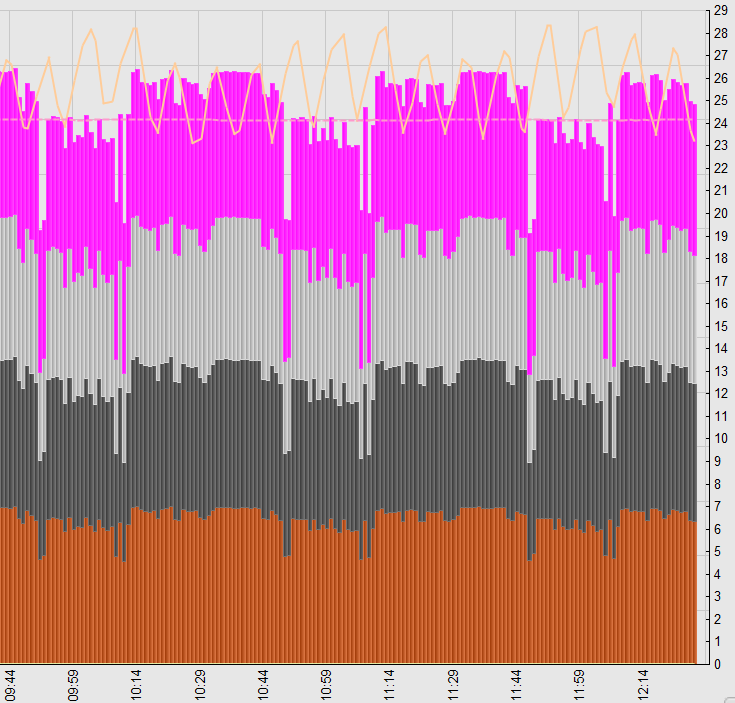

Analyze flow rates, detect losses and leaks, and visualize production cycles or idle periods on your air networks.

Monitor consumption at the inlet or outlet of your processes.

Interact with your machine environment using built-in digital inputs/outputs (standby, alarms, states, etc.).

Connect up to 6 sensors to monitor heat exchanges, heating and cooling across your installations.

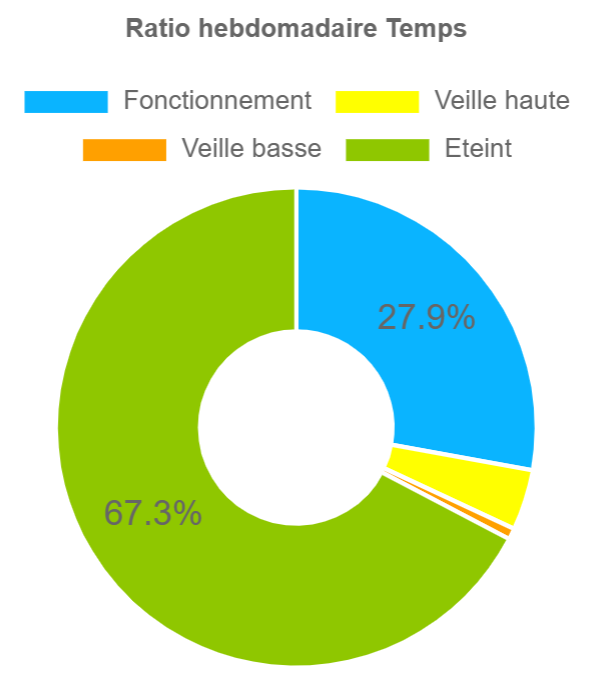

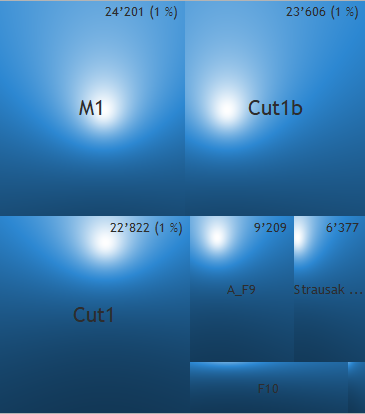

The device includes an algorithm capable of analyzing measured data in real time.

It generates relevant indicators such as energy sobriety rate, machine states, and economic efficiency rate.

We communicate using the protocols supported by your company: OPC UA, REST API, or directly at machine level.

Our device communicates safely using the industry’s most demanding security standards.

Your data remains confidential, even in a connected industrial environment..

A concrete solution for industrial energy efficiency.

© All Rights Reserved.

Pour offrir les meilleures expériences, nous utilisons des technologies telles que les cookies pour stocker et/ou accéder aux informations des appareils.